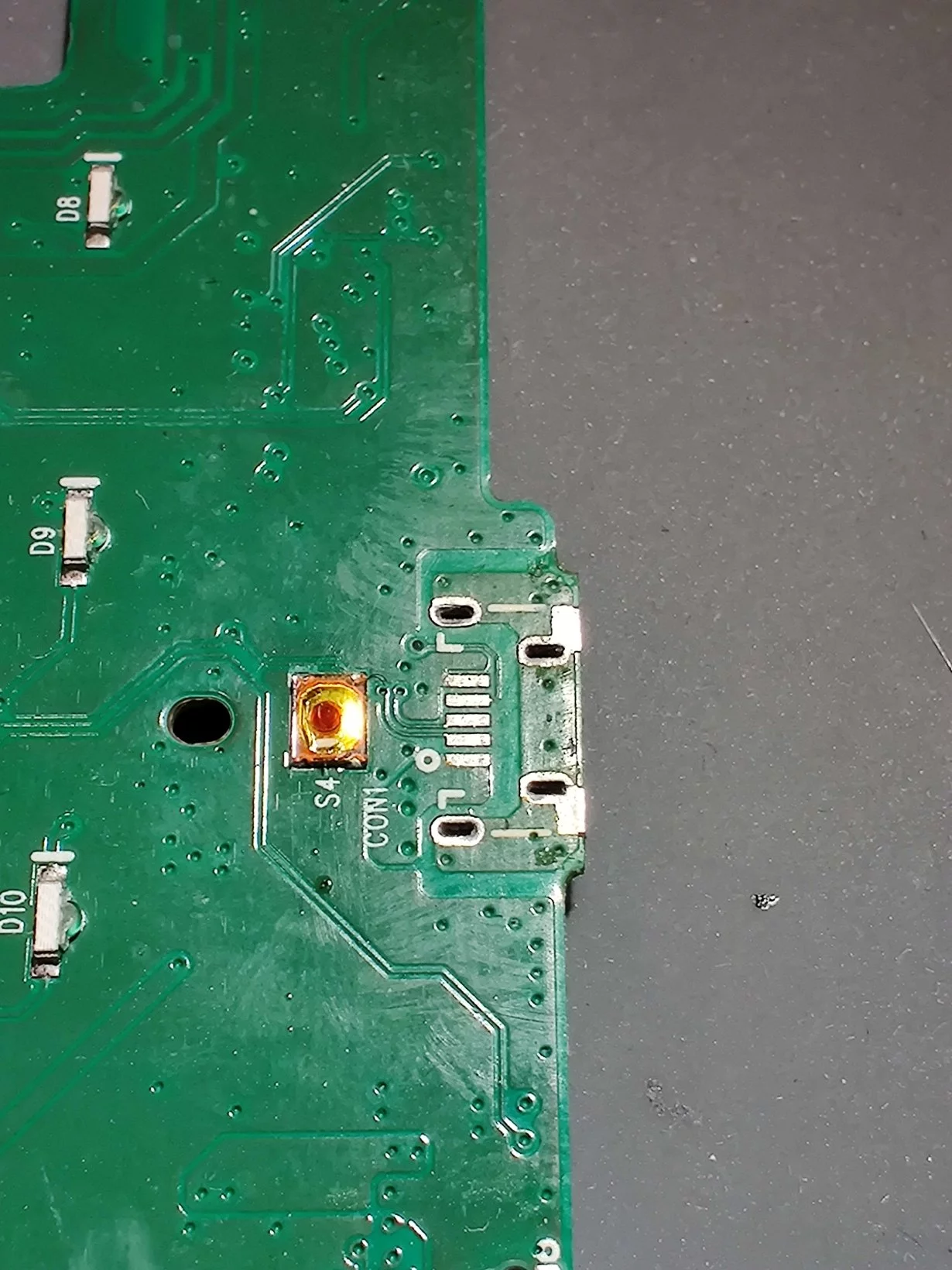

Tolino Shine 2HD - usb port repair

Repair of an unconventional footprint.

After removing the case with a plastic spatula and breaking almost all the clips the single PCB is revealed. The damaged USB connector is removed and the footprint is cleaned using solder wig.

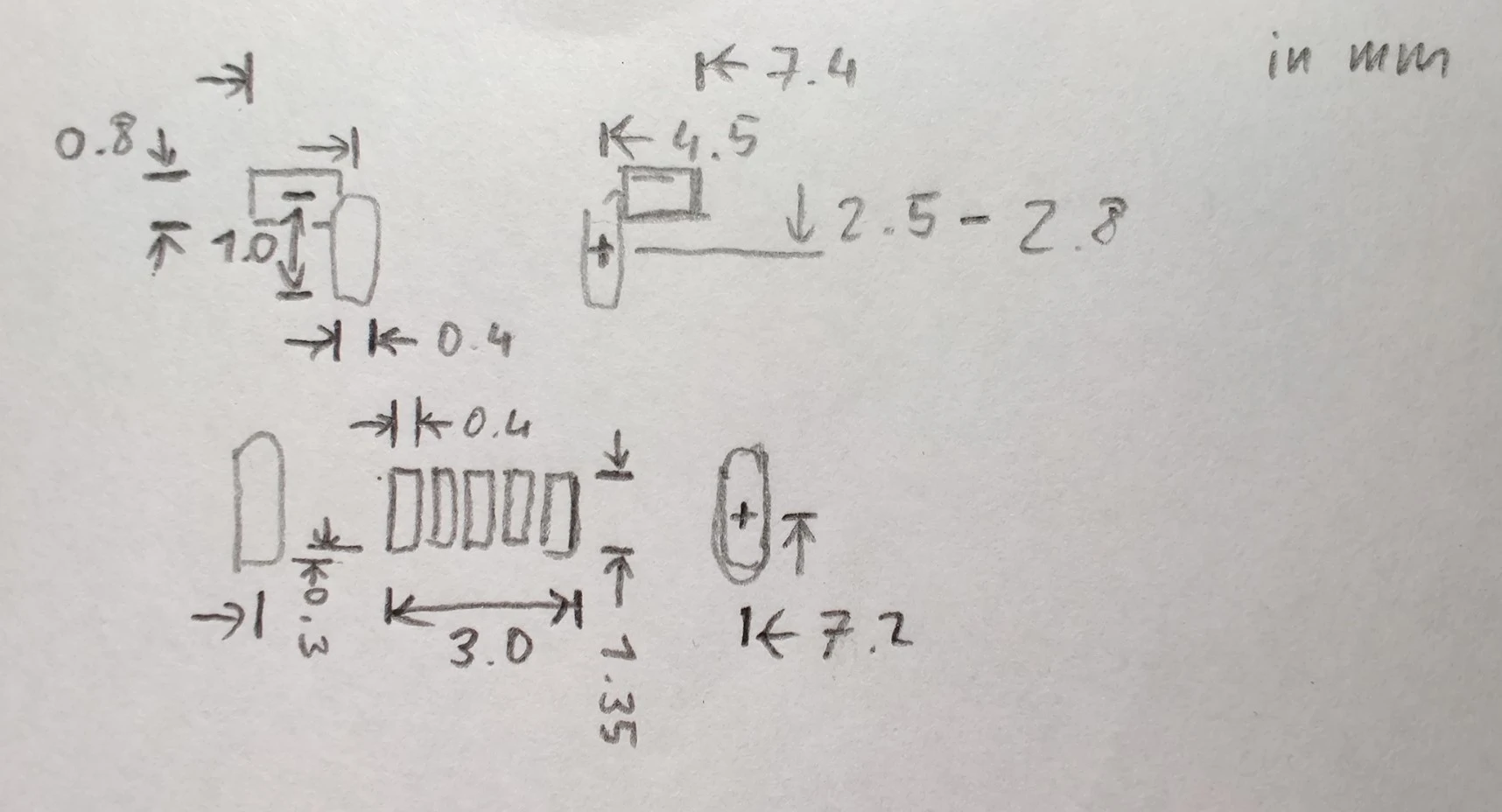

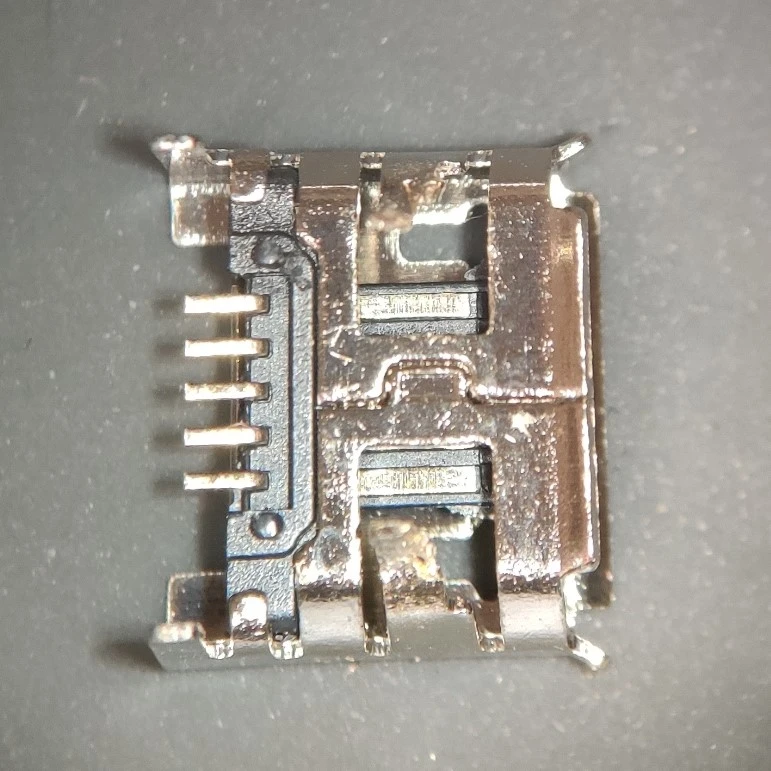

The dimensions depicted in the second figure have been measured with a caliper. The footprint is obviously designed to fit two different connectors, a through-hole version, and a smd-part. Connectors, especially if they are un-/plugged regularly, should be through-hole technology because of the superior mechanical stability. The layout of the through holes of this footprint however is very odd, because for most USB-micro connectors the two legs in the front are at least as far apart as the legs next to the data pins. For this reason, it has been impossible to find a direct replacement and so 3 generic models were bought from LCSC.

To fit the front two holes the legs in front have to be bent with needle nose pliers.

Applying UV-curable glue can further improve mechanical stability.